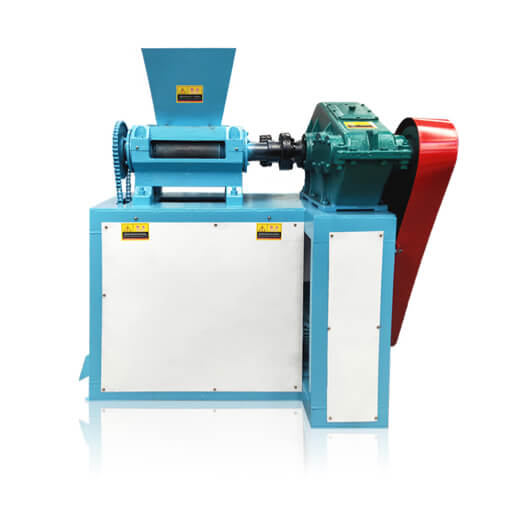

Product Description

Double roller granulator, which is also called roller extrusion machine, is the key machine to make dry powder into granules or pellets under room temperature, but with high granulation rate, the granules size can be 4-20mm and granules strength can reach 12-60N as required.

Application

The dry granulation machine or dry pellet machine with two rollers can be used in fields such as fertilizer, chemical, petrochemical, building materials, mining and metallurgy, environmental protection, printing and dyeing, ceramics, rubber, plastics, etc. Especially used in the granulation of fertilizer such as soda ash, borax, boric acid, ammunition chloride, ammonium sulfate, potassium chloride, potassium sulfate, ammonium chloride, salt, snow-melting agent.

Granulation Principle

This roller press granulator have two functions, Roller granulation system and breaking or crushing system.

The roller granulation system can expel all the air between crystals or powders through compression, making the bridge bonds between crystals short, thereby generating attractive forces such as van derWaals forces, adsorption forces, crystal bridges, and embedded connections, forming particles or pellets that meet the requirements.

The crushing system can break the Long strips of granules into small pieces. Then goes through the sieve under it to screen the powder or standard pellet or granules out.

Technical Data

|

Model |

SFR-100 |

SFR-150 |

SFR-200 |

SFR-300 |

|

Capacity/tph |

0.7-1.1 |

1.2-1.6 |

1.6-2.2 |

2.6-3.2 |

|

power |

15KW |

18.5KW |

30KW |

45KW |

|

Roller |

Forged with alloy steel,heat treatment in special process, the surface of roller is plated with hard chromium for rustproof and wear-resistant |

|||

|

Reducer |

Hard tooth surface dedicated reducer |

|||

|

Feed size |

≤0.5mm |

|||

|

End product size |

3.8mm,4.2mm,4.5mm,5mm,5.5mm,6.0mm,6.5mm,8mm,10mm, or customized size |

|||

|

Material moisture |

Inorganic material:2%~5%; organic material:6-12% |

|||

|

Working temperature |

Normal temperature |

|||

|

Granular shape |

Oval/oblate, irregular, strip, slice |

|||

Note: the parameters above only for reference, will revise accordingly from different materials and projects.