Product Description

The dry roller extrusion granulator or called hydraulic roller press granulation machine uses the dry compacting technology to compress powder materials with the moisture content of ≤ 5% into flakes or blocks, and then goes to crushing and sieving processes to make the flake and block materials into granules or tablets that meet the requirements. Dry compacting granulation machine, it mainly relies on external pressure, which press the material to pass through the gap between two rollers and compress into pieces. During the compact process, the actual density of the material can increase by 1.5-3 times to achieve a certain particle strength requirement.

Widely used

|

Fertilizer |

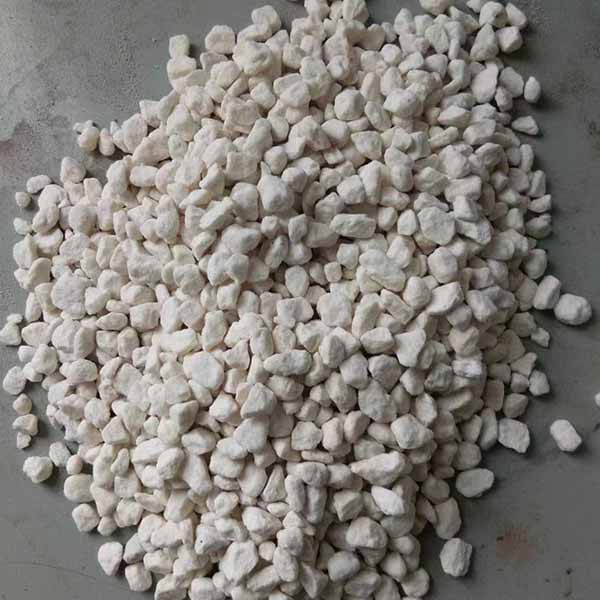

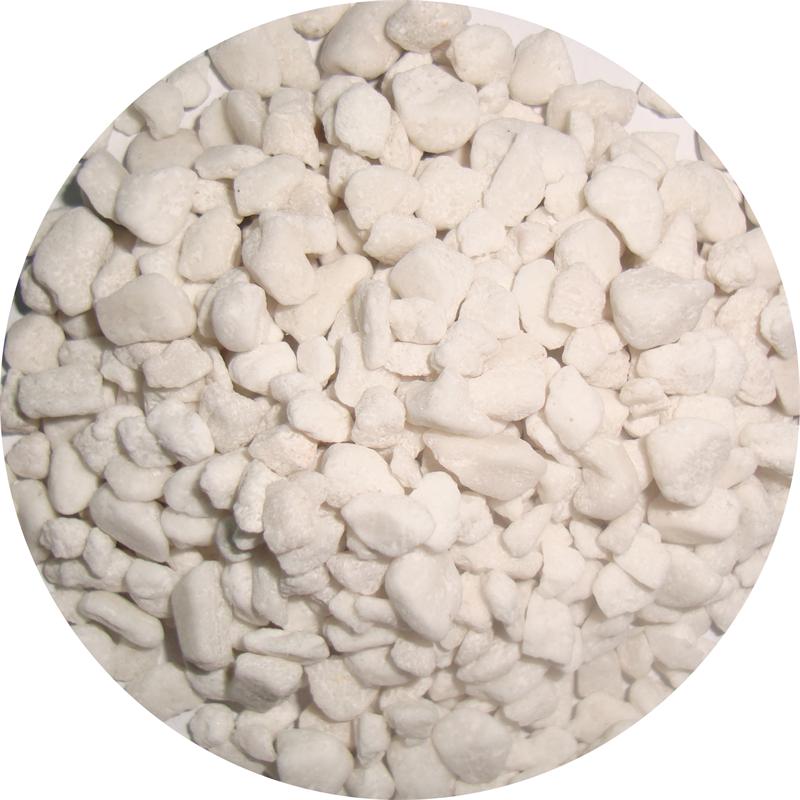

Potassium sulfate(SOP), potassium chloride(MOP), Russian red potassium, ammonium chloride, potassium nitrate, monoammonium phosphate, diammonium phosphate(DAP), ammonium sulfate(AS), ammonium bicarbonate. |

|

Powder |

Antioxidants, bleaching agents, zinc oxide, lead oxide, calcium chloride, potassium carbonate, cryolite, aluminum fluoride, brake powder, rubber and plastic additives, white carbon black, calcium aluminate, phosphate rock powder, fillers, feed additives, imidacloprid, steelmaking additives, snow melting agents, bentonite, aluminum oxide powder, phosphogypsum, desulfurization gypsum, beneficiation agents, as well as graphite, carbon black, etc |

Working principle

The powder materials are uniformly forced into the feeding hopper through a force feeder, and rollers rotate in reverse at the same speed. One set of roller bearing seats remains stationary inside the frame, while the other set of roller bearing seats move on the frame guide rails, using hydraulic cylinders to apply pressure and make them close to each other. There are many holes of the same shape and size arranged regularly on the surface of the rolling mill, and the valleys are aligned with the valleys. The dry powder material continuously and uniformly enters between the two rolling rolls from above, relying on its own weight and forced feeding. After entering the biting area, the material is gradually bitten into the trough by the rolling rolls. As the rolling mill rotates continuously, the space occupied by the material gradually decreases and is gradually compacted, reaching the maximum forming pressure. Subsequently, the pressure gradually decreases, and the pressure block falls off the hole due to its elastic recovery and self weight, entering the crushing, shaping, and screening device, ultimately forming qualified granular products.

Technical Data

|

Model |

SFDH360 |

SFDH450 |

SFDH650 |

SFDH850 |

SFDH1050 |

|

Roller diameter |

φ360 |

φ450 |

φ650 |

φ850 |

φ1050 |

|

valid usable |

170-230 |

190-280 |

290-330 |

420-450 |

450-500 |

|

Roller speed |

Adjustable |

||||

|

Max |

8 |

12 |

16 |

32 |

45 |

|

Flakes output*(t/h) |

1.3-2.3 |

2.5-3.5 |

5-7 |

12-22 |

22-45 |

|

Finished |

0.9-1.3 |

1.8-2.5 |

3.5-4 |

5-8 |

10-16 |

|

Granular size |

2-5 |

2-5 |

2-5 |

2-5 |

2-5 |

|

Main unit |

30-37 |

55-75 |

110-132 |

220-250 |

400-550 |

|

Total installed |

55 |

90 |

175 |

400 |

850 |

|

External |

2.350×2 |

2.6×2.2 |

3.6×2.8 |

5×3.8 |

7×5 |

|

Total weight |

7 |

10 |

21 |

46 |

93 |

Note: the parameters above only for reference, will revise accordingly from different materials and projects.