Product Description

It is used to granulate various organic compost raw materials after fermentation especially materials with much fiber such as straw. It does not need to crush the raw materials before granulation, and can directly make the compost into round granular after compost fermentation.

The mechanical stirring force of the high-speed rotation inside the granulator and The resulting friction force enables the powder material to be continuously blended, granulated, and strengthened to achieve the purpose of round granular. The moisture of raw materials can be granulated from 30%-50%. The finished particle diameter is generally between 1-10 mm, and the granulation rate can reach more than 90%.

It can be applied to organic compost fermented from animal waste such as chicken manure, pig manure, cow manure, sheep manure, carbon black, clay, kaolin and other light fine powder and so on.

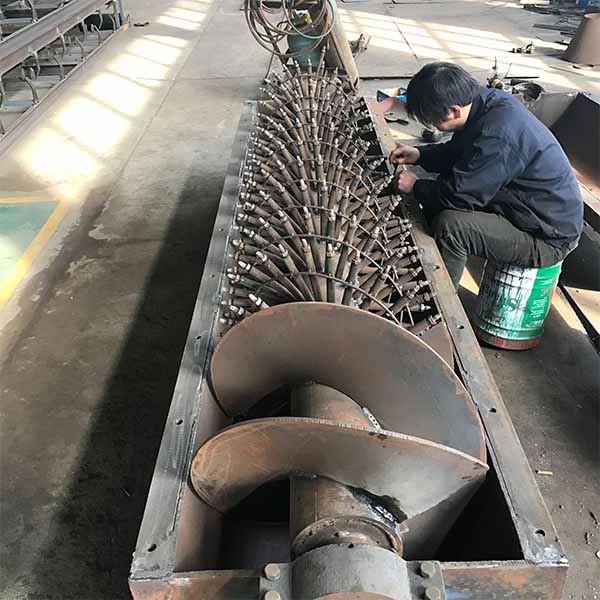

Working Principle

The powder material feeds into the tubular granulation machine from the entrance, and is continuously pushed and mechanically moved with the machine casing through the granulation rotor. By utilizing the high-speed rotating mechanical stirring force and the resulting friction force, the powdered compost material is continuously blended, granulated, , and strengthened inside the machine, to achieve the purpose of material granulation.

The size of particle granular diameter can be adjusted appropriately by the material mixing amount and spindle speed and also the moisture. Generally, the lower the mixing amount, the higher the speed, and the smaller the particles, and vice versa.

Technical Data

|

Model |

Power (kw) |

RPM |

Capacity (tph) |

Size/L*W*H (mm) |

Weight/ (kg) |

|

SFG-60 |

37 |

312 |

1-2 |

3710*960*1060 |

1400 |

|

SFG-80 |

45 |

242 |

2-3 |

3710*1260*1310 |

2800 |

|

SFG-100 |

55 |

373 |

3-4 |

3780*1450*1510 |

4500 |

|

SFG-120 |

75 |

450 |

4-5 |

4960*1800*1900 |

6800 |

|

SFG-150 |

90 |

578 |

5-6 |

5200*2300*2150 |

9200 |

Note: the parameters above only for reference, will revise accordingly from different materials and projects.