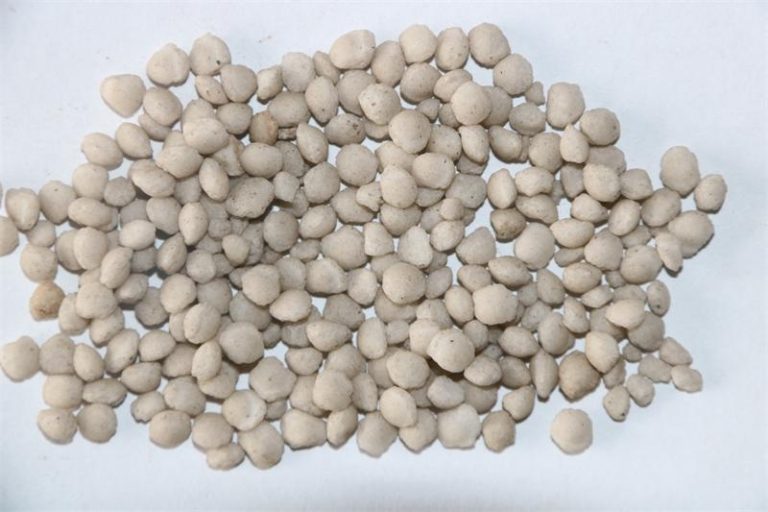

NPK fertilizer, which also called compound fertilizer, are fertilizers made by chemical and/or physical methods, with at least two of the three nutrients being labeled as nitrogen, phosphorus, and potassium, as well as micro elements such as Mn/Zn/Cu/Mo etc. Its appearance is granular, strip-shaped, or sheet-like products,

with no mechanical impurities.

The common granulation processes for NPK fertilizers include roller press granulation, rotary drum (steam) granulation, disc pan granulation, spray granulation, and High tower granulation.

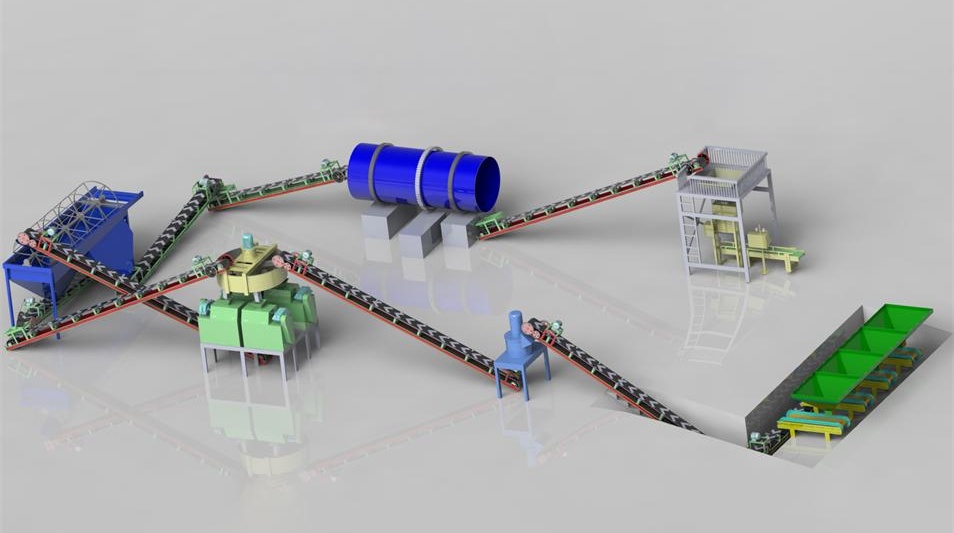

The main machines for the NPK fertilizer production line: automatic batching system, grinding machine, mixing machine, roller press granulator, rotary dryer machine, rotary cooler machine, rotary screener, rotary coating machine, packing machine, PLC controller, and belt conveyor to connect each machine.