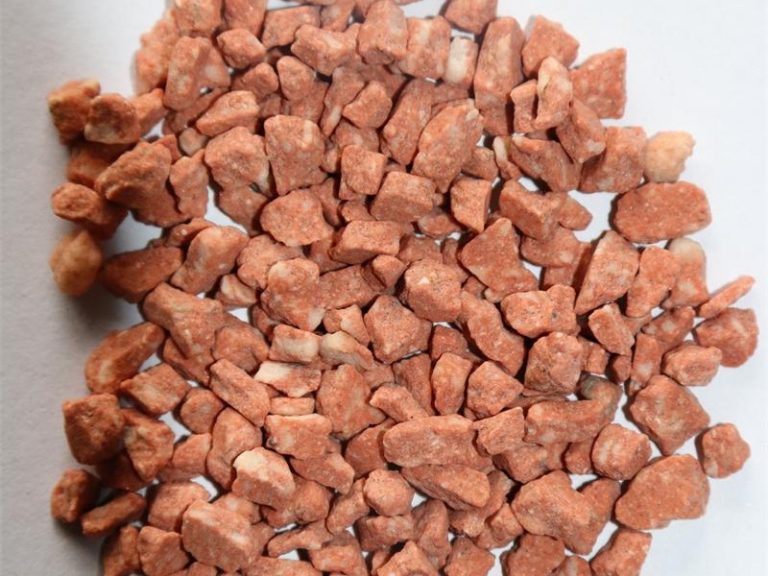

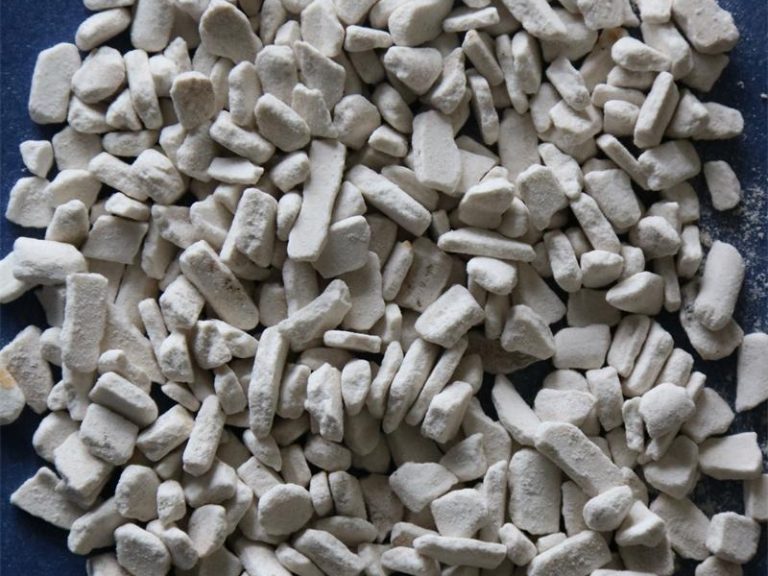

Hydraulic roller press pellet production line, which also called powder compaction granulation production line, is usually used to make fine powder into pellets or granules, especially in the granulation process of single fertilizer like ammonium chloride, ammonium sulfate, potassium chloride and NPK fertilizer and compound fertilizer.

In contrast to the wet granulation process, compaction-granulation requires neither drying nor the addition of binders. The granules or pellets have strong strength which can reach to max 60N.

The main machines for the MOP SOP granulation production line by hydraulic roller press granulator: Automatic batching system, grinding machine, mixing machine, hydraulic roller press granulator, breaking shaping machine, rotary screener, packing machine, PLC controller, and belt conveyor to connect each machine.