Organic-inorganic compound fertilizer is a type of compound fertilizer that contains both organic matter and an appropriate amount of chemical fertilizer. It is a commercial fertilizer granulated or directly mixed after harmless and effective treatment of organic materials such as feces and peat through microbial fermentation, and adding an appropriate amount of fertilizer, humic acid, amino acid or beneficial microbial bacteria.

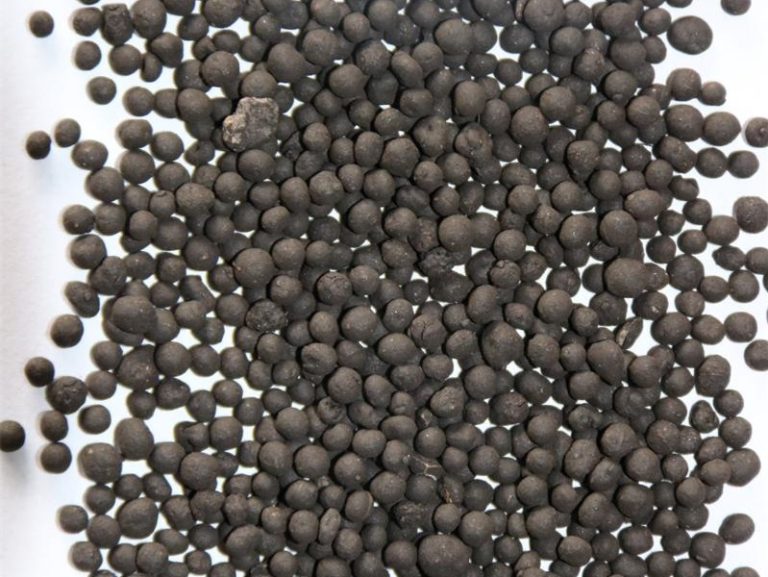

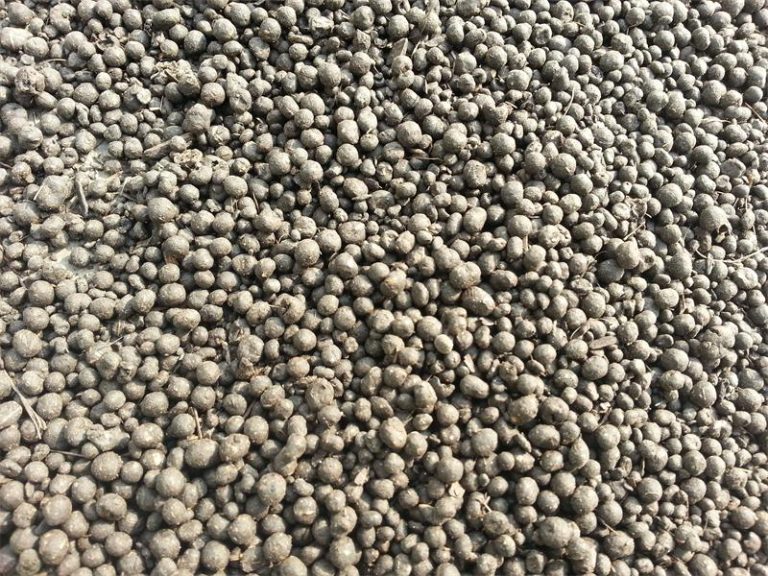

Appearance: Granular or strip-shaped product, without mechanical impurities.

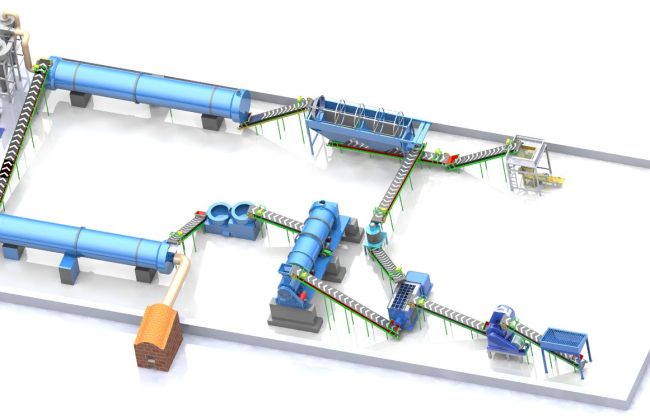

The main machines for the organic compound fertilizer disc granulator production line: fermentation turning machine or fermentation tank, automatic batching system, grinding machine, mixing machine, rotary drum granulator or pan granulator, rotary dryer machine, rotary cooler machine, rotary screener, rotary coating machine, packing machine, PLC controller, and belt conveyor to connect each machine.